Batch vs. Continuous Manufacturing

Is The Nanomaterials Industry Lagging or Leading?

In the world of manufacturing, two dominant paradigms vie for supremacy: batch and continuous processes.

At first glance, continuous manufacturing presents itself as a modern-day marvel – a seamless and constant production method that, on paper, seems to promise efficiency, consistency, and reduced waste. And yet, in a surprising twist of industrial reality, a vast majority of industries remain anchored to batch processes – including the nanomaterials industry.

This poses a thought-provoking question: Is the persistent reliance on batch manufacturing indicative of industries being mired in outdated practices? Or do underlying practical challenges cast shadows over the premise of continuous manufacturing? This article delves into the intricate factors guiding this industrial choice, revealing a landscape far more nuanced than it might initially appear.

Complete the form to have this article sent to your email.

Whether you have proof of concept or are interested in establishing proof of concept, Cerion can help. Our solutions-based approach allows us to quickly provide you with optimized candidate materials based on your specified product application to enable you to rapidly enable a path towards commercialization. Our team acts as an extension of your development team, following your lead to ensure both fit and scalability for commercialization.

From the material design stage, through scale-up and manufacturing – we focus on providing you with the customized materials you require. Our in-house teams of researchers, analytical chemists and engineers have decades of experience working with an expansive list of metal, metal oxide and ceramic nanomaterials, allowing our customers to rely on us no matter how much nanomaterial expertise they have coming into our partnership.

Interested in talking to our team about our capabilities or an upcoming project? Contact us to schedule time.

Download Batch vs. Continuous Manufacturing Article

Complete form to have this article emailed to you.

/orange-triangle-for-email-accent.png)

Nanomaterial Services

Design

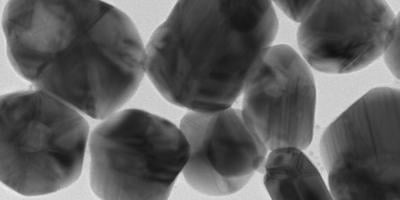

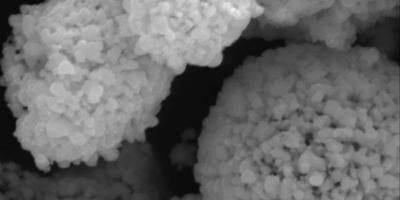

High degree of precision control over nanoparticle size and technical attributes to maximize nanomaterial performance

Scale-Up

Proven ability to scale up nanoparticles 1,000 to 10,000x their lab-scale counterparts while preserving critical design parameters

Manufacturing

Infrastructure designed to ensure companies can acquire cost-effective nanoparticles at pilot and industrial scale volumes

Synthetic Pathways

Despite their multiple diverse properties and many potential uses, companies often find it challenging to successfully incorporate nanomaterials into their products and systems for a number of reasons. Each method to produce nanoparticles is unique, with certain advantages and disadvantages. Identifying the optimal route will yield the best technical and cost performance for their product or application.

Nanomaterial Properties

When considering leveraging nanomaterials for a product or system, many companies focus on a single material or limited set of commercial, off-the-shelf materials, often running into several challenges - over-budget, imploded development timelines, and materials that aren't able to scale to commercial volumes. See examples of properties that can be leveraged across many use cases.